Leave Your Message

In today's rapidly evolving manufacturing landscape, the integration of innovative materials and designs plays a crucial role in enhancing efficiency and functionality. Among these materials, the aluminum handle has emerged as a standout feature, revolutionizing various modern processes. The lightweight yet durable nature of aluminum, combined with its versatility, allows manufacturers to create handles that not only improve ergonomics but also optimize production workflows.

From automotive assembly lines to consumer electronics, the application of aluminum handles transcends traditional boundaries, offering enhanced reliability and superior user experience. This blog will explore the top innovative applications of aluminum handles, highlighting their impact on modern manufacturing and the advantages they bring in terms of performance, sustainability, and design flexibility.

As industries continue to embrace cutting-edge solutions, the aluminum handle remains at the forefront of this transformation, setting new standards for efficiency and innovation.

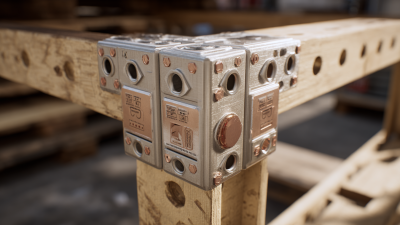

The design of aluminum handles has evolved significantly in recent years, reflecting the need for enhanced manufacturing efficiency. With their lightweight nature and robust strength, aluminum handles are increasingly being integrated into various manufacturing processes. One emerging trend is the use of ergonomic designs that prioritize user comfort and reduce fatigue during extended use. This not only improves the overall productivity of workers but also minimizes the risk of injuries, making the manufacturing environment safer.

Tips to consider when selecting aluminum handles include ensuring they are appropriately sized for the task and incorporating surface treatments that enhance grip. Additionally, exploring customizable designs can lead to innovations tailored to specific manufacturing processes, ultimately increasing efficiency and reducing the need for frequent replacements. As more manufacturers recognize the advantages of aluminum handles, we can expect to see a rise in their application, driving further advancements in design and functionality.

Another trend gaining traction is the incorporation of smart technology within aluminum handles. This can include built-in sensors that monitor usage patterns and provide feedback on handling techniques, contributing to better ergonomics and efficiency. By embracing such innovations, manufacturers can not only optimize their operations but also foster a culture of continuous improvement.

The integration of aluminum handles in modern manufacturing processes has significant implications for production costs and sustainability. According to a report by the Aluminum Association, aluminum can reduce overall weight by up to 30% compared to traditional materials like steel or plastic. This lightweight nature contributes not only to lower shipping costs but also enhances energy efficiency during transport. As manufacturers increasingly seek to optimize their supply chains, switching to aluminum handles can lead to a notable decrease in logistics expenses.

Furthermore, the environmental impact of utilizing aluminum is substantial. A study by the International Aluminium Institute indicates that the recycling rate of aluminum stands at around 75%, making it one of the most sustainable materials available. Given that aluminum can be recycled repeatedly without loss of quality, its application in production processes not only supports circular economy initiatives but also reduces the carbon footprint associated with raw material extraction and processing. This dual advantage of cost reduction and environmental sustainability positions aluminum handles as a smart choice for manufacturers aiming to innovate while being responsible stewards of the planet.

The field of material science is witnessing innovative transformations that greatly enhance the application of aluminum handles in modern manufacturing processes. With advancements in lightweight composite structures and energy-efficient materials, manufacturers can produce aluminum handles that are not only durable but also significantly reduce the environmental impact of their products. The lightweight nature of aluminum, combined with emergent production techniques, enables manufacturers to create handles that improve ergonomics without compromising strength.

Recent trends emphasize the incorporation of sustainable practices, as seen in the transition of major products from titanium to aluminum, which can result in substantial reductions in carbon footprints. This shift underscores the material's versatility and its growing appeal in various industries. Innovations such as low-cost aluminum batteries are on the horizon, promising further enhancements in sustainability and efficiency. The exploration of aluminum in diverse applications, from robotics in food industries to intelligent home construction, illustrates the material's pivotal role in driving the next generation of manufacturing solutions, making aluminum handles an essential component of modern manufacturing systems.

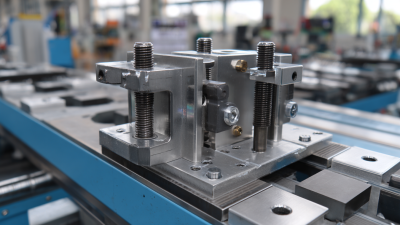

In the quest for lightweight tooling solutions, aluminum stands out as a front-runner, often surpassing traditional materials like steel and plastics. Its excellent strength-to-weight ratio allows manufacturers to create tools that are not only lighter but also maintain durability and resistance to wear. Furthermore, aluminum’s resistance to corrosion makes it suitable for various applications, from aerospace to automotive, where safety and performance are paramount.

When comparing aluminum to alternatives, it's essential to consider factors such as manufacturing costs and environmental impact. While aluminum may require a higher initial investment, its longevity and recyclability can lead to significant savings over time. Manufacturers also benefit from aluminum's malleability, which allows for innovative designs and easier customization.

Tip: When selecting materials for tooling solutions, always assess the trade-offs between weight, strength, and cost. Plan for a lifecycle analysis to understand how the material choice affects long-term operations and sustainability.

Another consideration is the machining process. Aluminum is generally easier to machine than alternatives, which can translate into faster production times and reduced labor costs.

Tip: Invest in quality cutting tools and proper machining techniques to maximize the benefits of aluminum. Regular maintenance of equipment can also enhance efficiency and prolong tool life.

As the manufacturing landscape continues to evolve, the shift towards aluminum handles showcases a significant trend driven by both innovation and efficiency. The lightweight yet durable properties of aluminum make it an ideal choice across various sectors, including automotive, aerospace, and consumer goods. With technological advancements and enhanced processing methods, manufacturers are beginning to leverage aluminum handles not just for functional purposes but also for their aesthetic appeal, creating products that are both practical and visually attractive.

Future projections indicate a robust market growth for aluminum handles, propelled by the increasing demand for sustainable and recyclable materials. Industries are recognizing the ecological benefits of aluminum, which can be recycled indefinitely without losing quality. Additionally, as manufacturers strive for cost-effective solutions to reduce weight and enhance product performance, the adoption of aluminum handles is expected to surge. This trend not only promises to meet regulatory standards for environmental impact but also aligns with the growing consumer preference for eco-friendly products, signaling a transformative phase in manufacturing practices.