Leave Your Message

In the world of transporting sensitive equipment, the design and durability of Road Case Latches play a crucial role in ensuring safety and efficiency. A recent industry report indicates that nearly 30% of equipment damage during transit can be attributed to inadequate fastening systems, highlighting the importance of reliable latches in protecting valuable gear.

With technological advancements and a growing emphasis on rugged durability, choosing the right Road Case Latch isn't just a matter of convenience; it's a fundamental aspect that can significantly impact the longevity of your equipment.

This blog will explore the seven best road case latches available on the market today, emphasizing their industry-approved designs that promise enhanced durability and security for professionals in various fields, from music production to photography and beyond.

When selecting road case latches, there are several top features to consider that will enhance durability and security. First and foremost, materials matter. Latches made from heavy-duty metals like stainless steel or zinc-plated steel provide superior resistance to corrosion and wear. These materials ensure that the latches can withstand the rigors of transport and handling, maintaining their functionality over time. Additionally, look for latches with a powder-coated finish, which not only adds an extra layer of protection but also helps in resisting scratches and other surface damage.

Another crucial aspect is the design of the latch. Choose latches that feature reinforced constructions, as they are likely to be more durable compared to standard options. Designs that incorporate weatherproof seals are also beneficial, especially for road cases exposed to various environmental conditions. Furthermore, ergonomic designs that facilitate easy handling and operation can make a significant difference in user experience, even in challenging situations. By prioritizing these key features, you can ensure your road cases are equipped with latches that not only meet industry standards but also enhance the overall longevity and reliability of your gear.

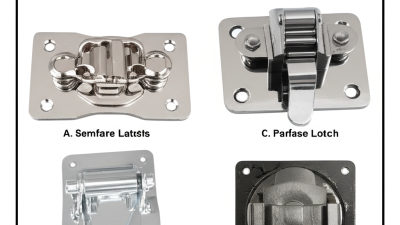

When it comes to securing valuable equipment during transport, road case latches play a crucial role in ensuring durability and reliability. According to a report by the National Association of Music Merchants, the growing demand for portable sound and lighting equipment has led to an increased focus on road case designs that prioritize security and ease of use. Various types of latches, including cam latches, draw latches, and butterfly latches, excel in different applications, depending on the specific needs of the user.

For instance, cam latches are widely favored in the music and live event industries for their quick-release capabilities, allowing for fast access during live performances. On the other hand, butterfly latches are often utilized for larger cases, providing a tighter seal to protect sensitive equipment from dust and moisture. A recent industry study revealed that cases featuring high-quality latches can increase equipment lifespan by up to 30%, proving that investing in reliable latch designs not only enhances functionality but also minimizes replacement costs over time. With a range of options available, selecting the right latch type in accordance with its intended use can significantly impact a road case's performance and durability.

When selecting road case latches, industry standards and approvals play a crucial role in ensuring quality and durability. Road cases are often subjected to harsh conditions, and the latches must withstand the rigors of transportation and handling. By adhering to accepted industry standards, manufacturers can guarantee that their products meet specific performance criteria, which includes considerations for strength, corrosion resistance, and ease of use. For instance, latches that comply with ANSI and ISO certifications provide assurance that they have been tested under rigorous conditions, enhancing their credibility in the market.

Furthermore, approved designs not only enhance the durability of road case latches but also contribute to user safety. Features such as locking mechanisms that are certified to industry standards help prevent accidental openings and potential damage to valuable equipment within the cases. Additionally, latches designed with user-friendliness in mind can reduce setup and teardown times, making them indispensable for professionals who rely on road cases for transport. Investing in industry-approved latches is not just about meeting requirements; it's about choosing reliability that can protect your gear while on the move.

When it comes to securing your gear during transport, proper installation of road case latches is crucial for durability and effectiveness. Begin by choosing high-quality latches that meet industry standards. This not only ensures strength but also enhances reliability during rugged use. It's important to select latches that are rust-resistant, especially if the items will be exposed to various environments. Assess the weight and size of the case and match them with appropriately rated latches to ensure they can withstand the strain.

Before installation, gather the necessary tools, including a drill, screws, and a level. Accurately measure and mark the positions for the latches to ensure they align correctly. When drilling, be careful to avoid splintering the material, which can compromise the case's integrity. After securing the latches, test them thoroughly. Make sure they operate smoothly and provide a tight seal. Regular maintenance checks can help identify any wear or damage to the latches over time, allowing for timely replacements that keep your equipment safe and secure during every journey.

| Latch Type | Material | Weight Capacity | Finish | Installation Complexity |

|---|---|---|---|---|

| Spring Loaded Latch | Stainless Steel | Up to 100 lbs | Polished | Easy |

| Compression Latch | Zinc-Plated Steel | Up to 150 lbs | Matte Black | Moderate |

| Butterfly Latch | Aluminum | Up to 75 lbs | Anodized | Easy |

| Draw Latch | Plastic | Up to 50 lbs | Black | Very Easy |

| Locking Latch | Steel | Up to 120 lbs | Chrome | Moderate |

| Slide Latch | Aluminum | Up to 95 lbs | Brushed | Easy |

| Toggle Latch | Stainless Steel | Up to 110 lbs | Polished | Moderate |

When it comes to ensuring the longevity of road case latches, regular maintenance is crucial. Road case latches are designed to withstand the rigors of transportation, but they still require attention to stay in top condition. One of the best practices is to periodically inspect each latch for signs of wear or damage. Look for any rust or corrosion, particularly in areas that are frequently exposed to moisture. Clean the latches with a soft cloth and a mild cleaning solution to remove dirt and debris, which can hinder their performance.

Lubrication is another key aspect of maintenance that can significantly enhance the lifespan of your latches. Applying a suitable lubricant periodically helps keep the latch mechanisms operating smoothly. Choose a lubricant that is appropriate for the material of your latches—whether it’s stainless steel or aluminum. Avoid over-lubricating, as this can attract dust and grime, leading to more problems down the line. Additionally, make sure to tighten any loose screws or bolts to ensure that the latches are secure, which will further bolster their durability during transit. By incorporating these maintenance practices, users can ensure their road case latches remain reliable and functional, providing peace of mind for every journey.