Leave Your Message

When embarking on a new project that requires precision and reliability, selecting the right tools is crucial. One such tool that often plays a vital role in achieving optimal results is the 90 Degree Toggle Clamp. These clamps are designed for quick, efficient holding in various applications, making them indispensable for woodworkers, metalworkers, and DIY enthusiasts alike.

In this ultimate guide, we'll delve into the essential factors to consider when choosing the best 90 Degree Toggle Clamp for your specific needs. From understanding the different types and their unique functionalities to assessing features such as material and load capacity, our comprehensive overview will empower you to make an informed decision. Whether you're securing workpieces for assembly, machining, or welding, the right 90 Degree Toggle Clamp can enhance your project's efficiency and safety, ensuring that you achieve professional-level results every time.

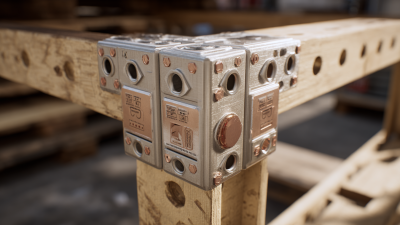

90-degree toggle clamps are essential tools in various industrial applications, offering versatility and precision in workholding. Understanding the functionality and design of these clamps allows users to select the best option tailored to their specific project needs. These clamps operate by using a simple lever mechanism that can securely hold objects in place with minimal effort. As technology advances, hydraulic, pneumatic, and electric swing clamps have emerged, allowing for enhanced operational efficiency. With clamping arms that rotate 90 degrees, these modern clamps provide user-friendly and reliable solutions for securing workpieces.

According to recent industry reports, the demand for innovative clamping solutions has grown significantly, with estimates showing a market expansion projected to reach over $2 billion by 2025. This increase is attributed to the rising need for automation in manufacturing processes, where quick and secure fastening is crucial. Additionally, the integration of smart technologies into clamping systems is a trend that reflects the evolving landscape of workholding solutions. As manufacturers continue to seek improved productivity and safety, selecting the right 90-degree toggle clamp will play a critical role in achieving optimal results for your next project.

| Clamp Type | Load Capacity | Jaw Opening | Material | Price Range |

|---|---|---|---|---|

| Horizontal Toggle Clamp | 500 lbs | 0-2 inches | Steel | $20 - $30 |

| Vertical Toggle Clamp | 300 lbs | 1-3 inches | Aluminum | $15 - $25 |

| Push-Pull Toggle Clamp | 400 lbs | 0-4 inches | Stainless Steel | $25 - $35 |

| Quick Release Toggle Clamp | 600 lbs | 0-2.5 inches | Carbon Steel | $30 - $40 |

| Heavy Duty Toggle Clamp | 1000 lbs | 0-3 inches | High Strength Steel | $50 - $70 |

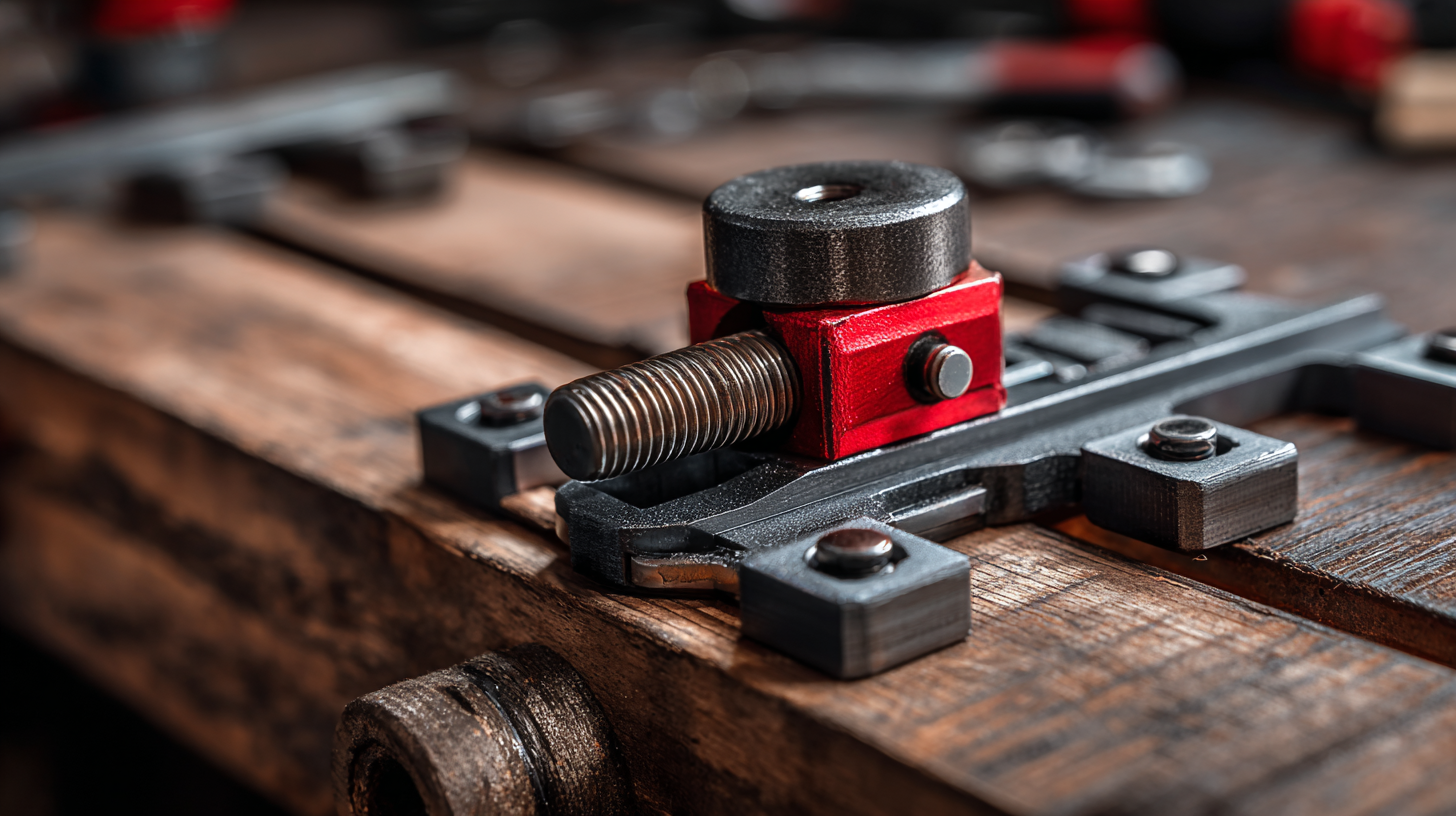

When selecting a 90-degree toggle clamp for your project, it's essential to consider several key features that can significantly impact both performance and usability. One of the primary features to look for is the clamp’s holding capacity, which determines how much force it can exert. Be sure to choose a clamp that fulfills the specific requirements of your project, whether you are working with lightweight materials or heavier components.

Another important factor is the construction material of the clamp. High-quality toggle clamps are typically made from strong materials like stainless steel or heavy-duty plastic, ensuring durability and longevity even in demanding environments. Additionally, pay attention to the clamp's ergonomics; a comfortable handle and smooth operation can make a significant difference, especially during repetitive use. Finally, consider the mounting options available. Different projects may require different types of installations, so selecting a clamp that can be easily and securely mounted in your workspace is crucial for operational efficiency.

When selecting a 90-degree toggle clamp, understanding the different types available is crucial to ensuring it meets your specific needs. There are several primary types of 90-degree toggle clamps, each designed for unique applications. For heavy-duty projects, consider vertical toggle clamps, which provide strong holding power and can handle significant pressure. On the other hand, horizontal toggle clamps are ideal for applications requiring low profile designs, allowing for easier access and operation in tighter spaces.

Tips for selecting the right clamp include assessing the material you will be working with. If you need to clamp delicate materials, opt for clamps with softer tips or rubber padding to avoid any marking or damage. Additionally, pay attention to the clamp’s maximum load capacity. Selecting a clamp that can comfortably handle the weight of your project ensures safety and durability in your work.

Another key factor to consider is the clamping speed. For projects that require frequent adjustments, look for toggle clamps that offer quick release mechanisms. This will streamline your workflow, making the work process more efficient and saving valuable time, especially in production environments.

When selecting the best 90-degree toggle clamp for your next project, it's essential to compare the myriad of brands available in the market to find one that aligns with your specific needs. In 2020, the global tools market saw significant growth, driven in part by the increasing demand for efficient and durable clamping solutions. Research indicates that toggle clamps are an integral component in various manufacturing processes, providing stable and secure holds especially in woodworking and automotive applications.

Among the top brands on the market, each offers distinct features and benefits. For instance, some brands emphasize ergonomic designs that enhance user comfort and efficiency during repetitive tasks, while others focus on durability, using high-grade materials to withstand heavy-duty use. Independent industry reports have shown that a well-chosen toggle clamp can improve productivity by reducing setup times and ensuring precision in alignment, making it a crucial investment for contractors and DIY enthusiasts alike.

To ensure the longevity of your 90-degree toggle clamp, regular maintenance is essential. First and foremost, keep the clamp clean from dust and debris that can accumulate from usage. A soft cloth or brush can effectively remove particles. Additionally, inspecting the clamp for any signs of wear or damage is crucial. Pay close attention to the pivot points and the locking mechanism to ensure they are functioning correctly. Any signs of rust or corrosion should be addressed immediately, as these can compromise the clamp’s integrity.

Lubrication also plays a vital role in extending the lifespan of your toggle clamp. Using a high-quality lubricant on the moving parts will minimize friction and wear, allowing for smoother operation. It’s advisable to apply lubricant periodically, especially after extensive use or exposure to moisture. Furthermore, storing the clamp in a dry environment when not in use can prevent rust and deterioration. By adhering to these maintenance tips, you can enhance the performance and durability of your 90-degree toggle clamp, making it a reliable tool for your projects.