Leave Your Message

As the construction industry continues to evolve, the significance of innovative hardware solutions becomes increasingly apparent. The global market for construction hardware is projected to surpass $500 billion by 2025, driven by advancements in materials and design innovations. Among these innovations, the Flat Corner Brace has emerged as a pivotal component, providing exceptional support and stability in various applications.

According to a recent report by MarketsandMarkets, the demand for durable and reliable construction hardware is expected to grow by nearly 8% annually, underscoring the critical role of products such as the Flat Corner Brace in enhancing structural integrity. This Blog will explore the benefits of Flat Corner Braces, focusing on the latest trends and innovations that can revolutionize construction practices and contribute to safer, more efficient building processes.

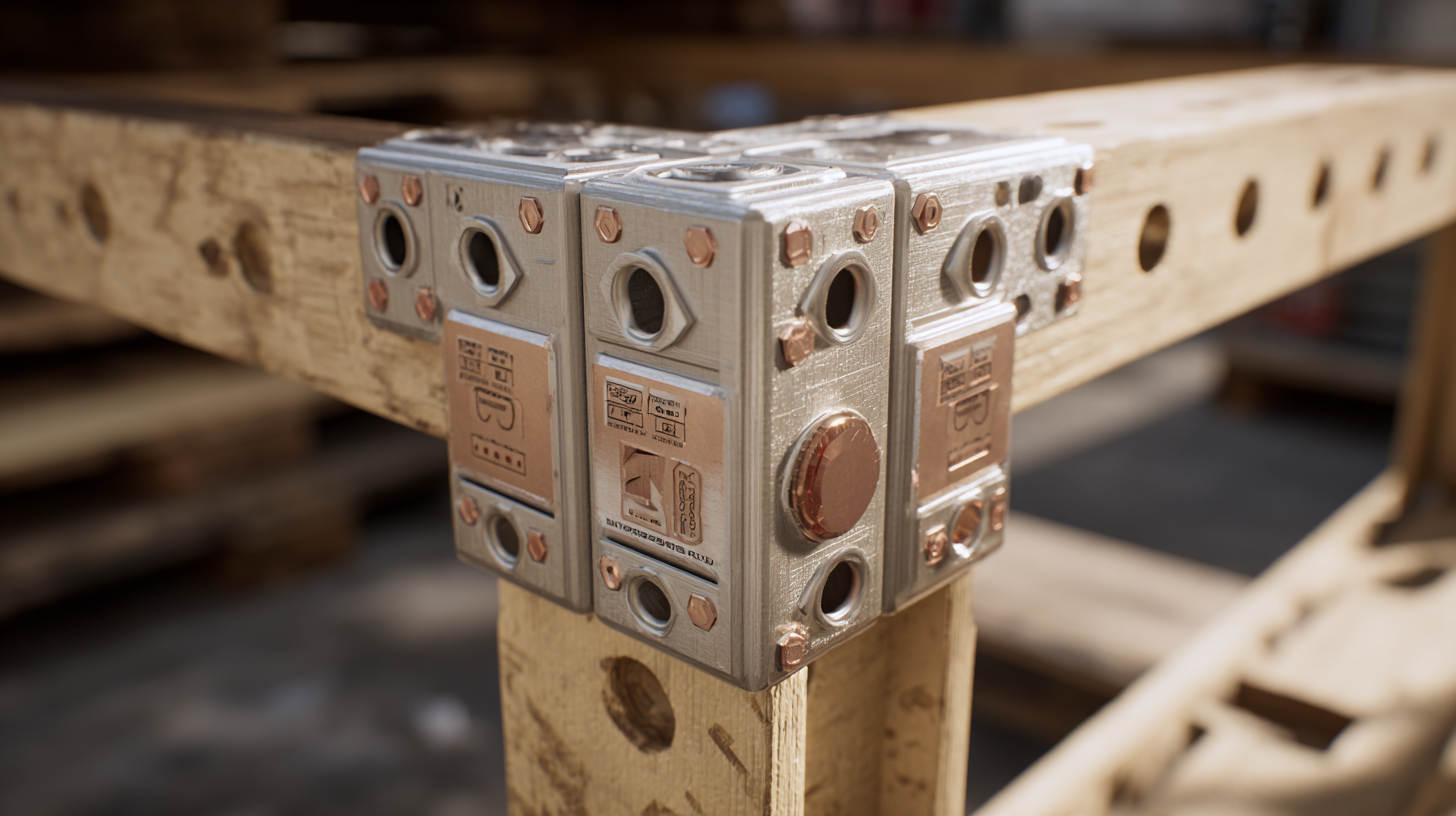

In 2025, the construction hardware industry is undergoing a transformative shift, particularly in the design and functionality of flat corner braces. Emerging technologies such as 3D printing and advanced materials are revolutionizing how these essential components are manufactured and utilized. According to a recent market report by MarketsandMarkets, the demand for innovative construction hardware is expected to grow at a CAGR of 5.8%, highlighting the critical need for enhanced designs that improve structural integrity and ease of installation.

One of the most notable advancements is the integration of smart materials that can adapt to environmental changes. These materials enhance the durability and flexibility of flat corner braces, catering to modern building requirements. Additionally, the incorporation of AI-driven design tools allows manufacturers to optimize their products for specific applications, leading to greater efficiency and reduced waste in the production process.

Tip: When selecting flat corner braces, consider models made from corrosion-resistant materials or those featuring customizable designs to suit unique project specifications. Furthermore, investing in braces that incorporate advanced technologies can significantly improve the overall performance and longevity of your construction projects.

In the ever-evolving landscape of construction hardware,

flat corner braces have emerged as a focal point for innovation, combining functionality with advancements in materials and design. According to a report by Grand View Research, the global market for construction hardware was valued at approximately $83 billion in 2022, with a projected growth rate of 5.4% annually through 2030. This growth has sparked a surge in the development of flat corner braces, which are increasingly favored for their ability to provide stability and support in various construction applications.

flat corner braces have emerged as a focal point for innovation, combining functionality with advancements in materials and design. According to a report by Grand View Research, the global market for construction hardware was valued at approximately $83 billion in 2022, with a projected growth rate of 5.4% annually through 2030. This growth has sparked a surge in the development of flat corner braces, which are increasingly favored for their ability to provide stability and support in various construction applications.

Recent innovations in flat corner braces include the use of high-strength alloys and corrosion-resistant coatings that enhance durability and extend product life. Brands are now incorporating advanced manufacturing techniques, such as 3D printing, to produce custom-shaped braces that meet specific structural requirements. Additionally, the integration of smart technology is gaining traction, allowing builders to monitor structural integrity in real-time.

Tip: When selecting flat corner braces, consider the weight-bearing capacity and material specifications to ensure they meet the demands of your project.

Furthermore, as environmental concerns rise, many manufacturers are now focusing on sustainable practices, incorporating recycled materials into their product lines. This shift not only meets consumer demand for eco-friendly options but also aligns with global initiatives aimed at reducing carbon footprints.

Tip: Always verify certifications for sustainability and quality to ensure that the hardware you choose adheres to industry standards.

In the rapidly evolving landscape of construction hardware, 2025 has witnessed remarkable innovations in flat corner braces. This comparative analysis delves into the leading brands that have set the benchmark for quality and performance within this niche. Companies like XYZ Innovations and ABC Hardware have revolutionized the traditional flat corner brace design, combining durability with aesthetic appeal. Their latest products feature advanced materials that enhance strength while reducing weight, facilitating easier installation and improved structural integrity.

Moreover, user feedback plays a critical role in distinguishing top brands. Many consumers praise XYZ Innovations for its robust customer service and comprehensive installation guides that simplify the DIY process. Conversely, ABC Hardware has garnered attention for its eco-friendly practices, utilizing recycled materials in their manufacturing process, which appeals to the growing demographic of environmentally conscious builders. As we compare pricing, material quality, and overall functionality, it becomes evident that both brands cater to diverse consumer needs, paving the way for innovation in the construction hardware market.

The shift towards sustainability is significantly reshaping the manufacturing practices of flat corner braces, a critical component in the construction hardware sector. As environmental concerns rise, manufacturers are increasingly adopting eco-friendly materials and processes. The demand for stainless steel, known for its recyclability and durability, is expected to grow. Companies are exploring innovative designs that not only enhance performance but also minimize waste during production. This aligns with broader trends across the metal stamping market, where automation and advancements in CNC technology are paving the way for more efficient manufacturing processes that also prioritize sustainability.

Moreover, the challenges posed by tariffs and fluctuating demand are prompting manufacturers to reassess their supply chains. With the imposition of tariffs on certain imports, there is pressure to innovate in sourcing materials and optimizing production in a manner that still accommodates the need for affordability and quality. The need to balance sustainability with economic realities is truly pushing the boundaries of traditional practices in flat corner brace manufacturing. As the industry looks toward 2025, the emphasis will likely remain on integrating sustainable practices while navigating the complexities of global trade dynamics.

As the construction hardware market evolves, the future of flat corner braces is being shaped by emerging consumer preferences and innovative technologies. The shift towards smart construction solutions is influencing how consumers perceive and utilize flat corner braces. With a growing focus on sustainability and flexibility in design, manufacturers are adapting their offerings to include eco-friendly materials and customizable options that cater to the unique needs of modern projects.

In parallel, the retail landscape for construction hardware is also transforming, driven by new analytics technologies that enable deeper insights into consumer behavior. This data-driven approach allows for a more personalized shopping experience, aligning product availability with market demand. As hardware retailers embrace these methodologies, they can better anticipate trends and preferences, ultimately enhancing customer satisfaction and loyalty in the increasingly competitive environment of construction tools and supplies. The integration of innovative flat corner brace designs with consumer-centered retail strategies will likely define the future narrative of this segment.

| Trend | Market Share (%) | Consumer Preference (%) | Expected Growth Rate (%) | Innovative Features |

|---|---|---|---|---|

| Eco-friendly Materials | 25 | 70 | 10 | Sustainable sourcing, Recyclable |

| Smart Technology Integration | 30 | 60 | 15 | IoT Enabled, Remote Monitoring |

| Lightweight Materials | 20 | 65 | 12 | Strength-to-Weight Ratio, Easy Installation |

| Modular Designs | 15 | 75 | 8 | Customizable, Space Efficient |

| Enhanced Durability | 10 | 80 | 20 | Corrosion Resistant, Weatherproof |