Leave Your Message

Choosing the right strut hinge can significantly impact the functionality and aesthetics of your project, but with an array of options available, it can often feel overwhelming. This ultimate guide aims to demystify the process of selecting the perfect strut hinge by exploring the various factors to consider, such as material, load capacity, and design requirements. Whether you're working on a DIY project, a professional build, or simply looking to upgrade your existing hardware, understanding the nuances of strut hinges is crucial.

By the end of this guide, you will have the insights and knowledge needed to make an informed decision, ensuring your project not only meets your practical needs but also adheres to your stylistic vision. Join us as we delve into the essential elements that will help you successfully navigate the world of strut hinges.

By the end of this guide, you will have the insights and knowledge needed to make an informed decision, ensuring your project not only meets your practical needs but also adheres to your stylistic vision. Join us as we delve into the essential elements that will help you successfully navigate the world of strut hinges.

When embarking on a project that requires the use of strut hinges, it's essential to understand the various types available. Strut hinges, often overlooked, play a pivotal role in providing structural support and facilitating movement in applications ranging from cabinetry to industrial machinery. According to a recent report by the Market Research Future, the global market for hinges, including strut hinges, is expected to witness a compound annual growth rate (CAGR) of 5.6% over the next five years, highlighting their increasing importance in various industries.

Strut hinges are commonly categorized into several types including gas struts, spring struts, and adjustable struts. Gas struts, for instance, are renowned for their ability to provide consistent lifting force and are ideal for applications like vehicle hoods and desks. Spring struts, on the other hand, offer simplicity and cost-effectiveness, making them a popular choice in lightweight installations. A study by the International Journal of Engineering Research & Technology states that selecting the appropriate type of strut hinge can enhance the functionality and longevity of the product, potentially reducing replacement costs by as much as 30%. Understanding these distinctions ensures that you choose the right strut hinge that meets the specific demands of your project.

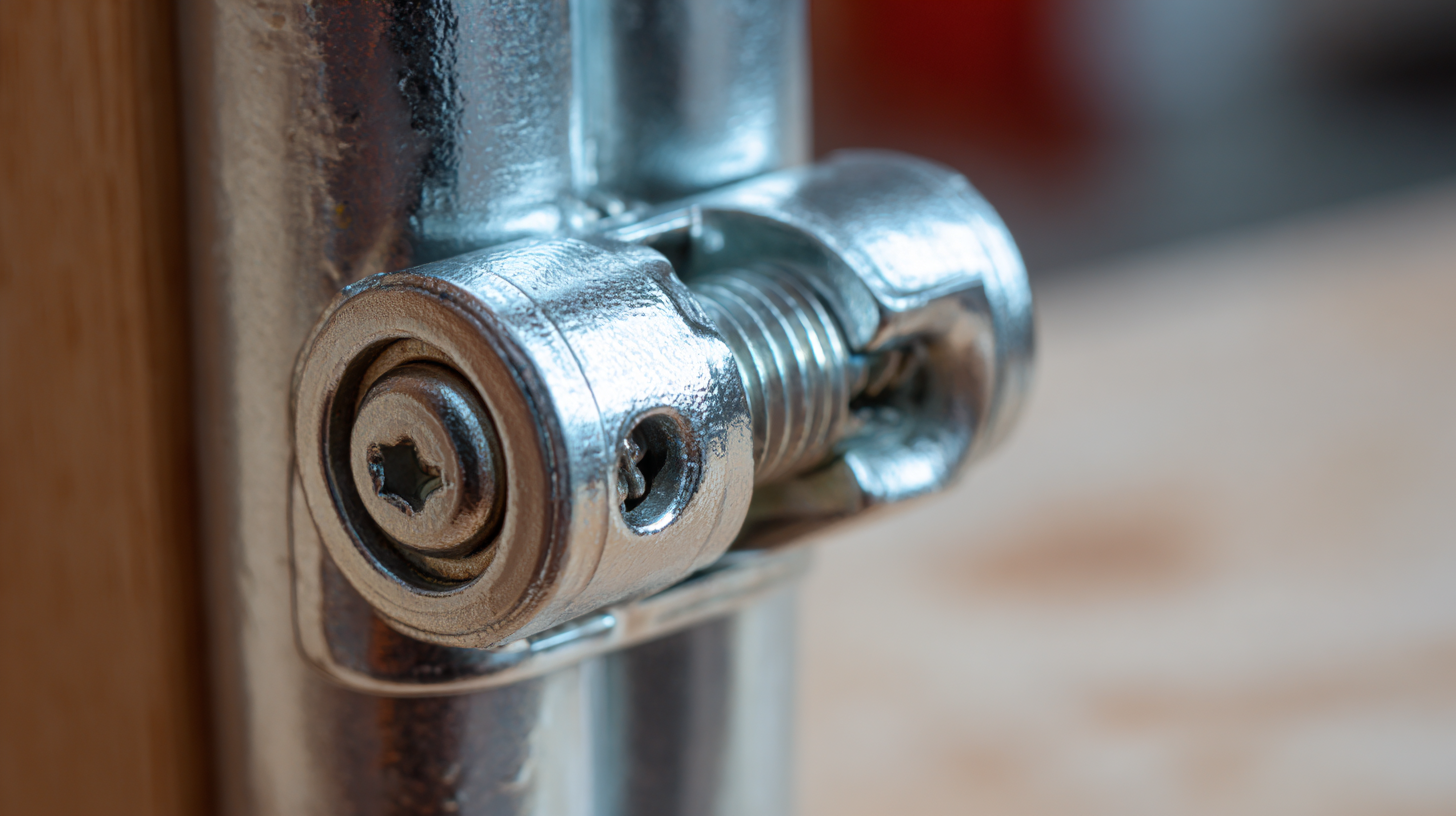

When selecting the right strut hinges for your projects, there are several key factors to consider that are essential to ensure optimal performance and compatibility. One of the primary considerations is the load capacity of the hinge. According to industry reports, the load rating typically ranges from 20 to 400 pounds depending on the hinge type and application. Understanding the specific requirements of your project allows you to choose a strut hinge that can withstand the necessary weight without compromising safety or functionality.

Another crucial factor is the material composition of the hinge. High-quality materials such as stainless steel or aluminum significantly enhance the durability and resistance to environmental factors, which is vital for outdoor or industrial applications. Additionally, consider the pivot point and angle of operation, as these can affect the efficiency of movement. As emphasized by experts in the field, hinges should provide smooth operation while reducing stress on adjoining components, contributing to the overall longevity of the project. Engaging in thorough research and consultation with manufacturers can lead to informed decisions that catalyze successful project outcomes.

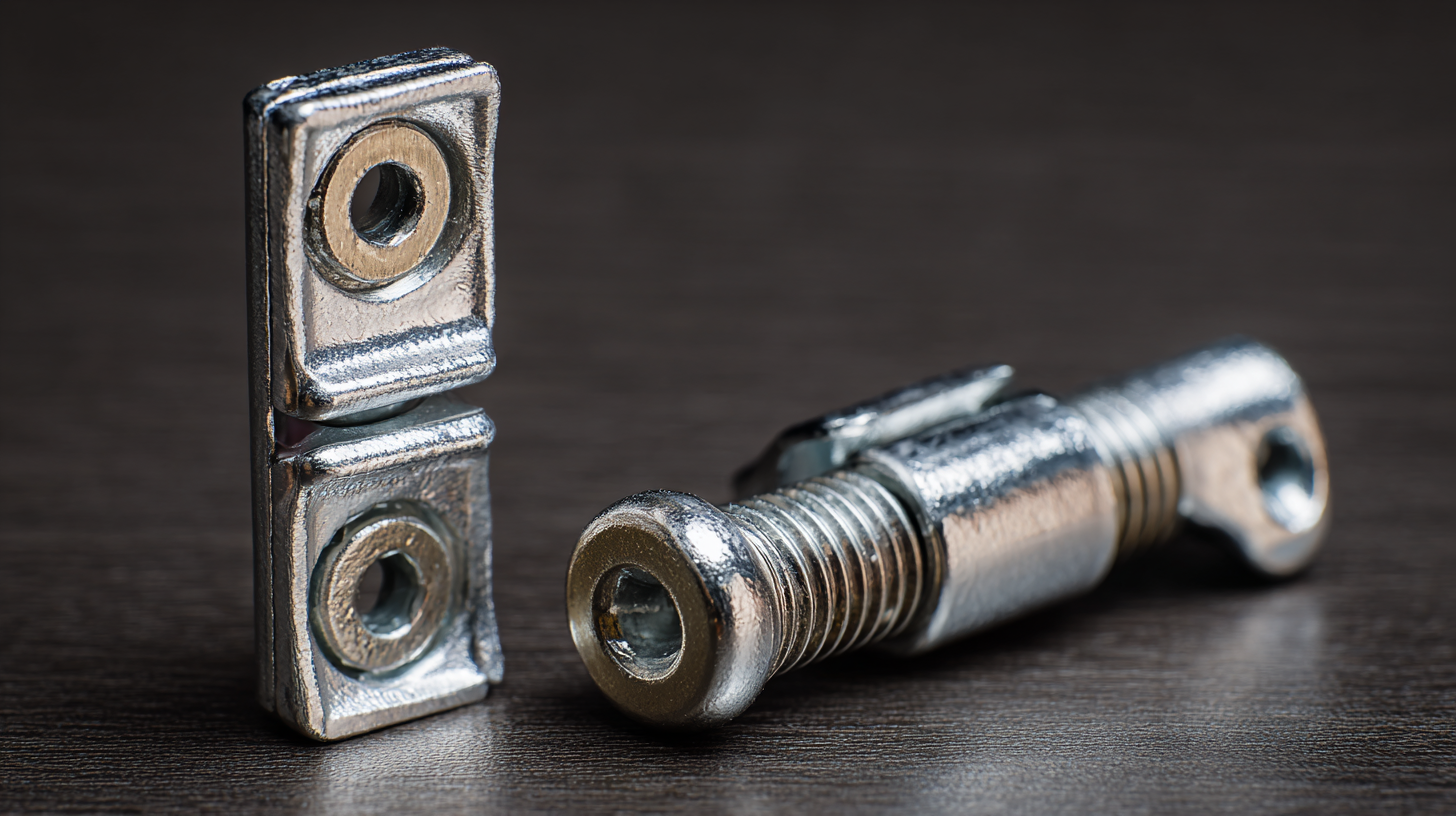

When selecting the right strut hinge for your project, understanding the materials used is crucial for ensuring durability and functionality.

The automotive door hinges market offers a range of materials, each with distinct properties that cater to different requirements.

Steel, for example, is favored for its strength and resistance to wear, making it a reliable choice for both passenger cars and commercial vehicles. Its robust nature allows it to withstand heavy usage, though it may be more prone to corrosion if not treated properly.

On the other hand, aluminum hinges provide a lightweight alternative that is highly corrosion-resistant, making them ideal for applications where weight reduction is a priority. This material is particularly valuable in the automotive industry, offering enhanced fuel efficiency and agility without compromising strength.

Additionally, emerging materials such as composite hinges are gaining traction due to their potential for reduced weight and increased resistance to environmental factors.

Ultimately, the choice of material will significantly impact the performance and longevity of the strut hinges in your projects, making careful consideration essential.

Strut hinges are essential components in various industries, providing the needed mechanical support for numerous applications. Their versatility allows them to be used in automotive, aerospace, and even furniture manufacturing. For instance, in the automotive sector, strut hinges are often utilized in vehicle tailgates and hoods, ensuring secure and stable operations while being able to withstand substantial forces during use. According to industry reports, the global market for strut hinges is projected to grow significantly, reflecting their critical role in manufacturing processes.

Moreover, beyond the automotive industry, strut hinges are widely applied in aerospace for cargo doors and maintenance access panels. Their ability to endure extreme conditions, such as high pressure and fluctuating temperatures, makes them ideal for such applications. Furthermore, the furniture industry has also seen a rise in the use of strut hinges in the design of innovative storage solutions, confirming their importance in modern product development. This adaptability across various fields underscores the necessity for careful selection of the right strut hinge to ensure optimal performance and longevity in any project.

When it comes to ensuring the longevity of strut hinges, proper installation and routine maintenance are paramount. Experts suggest that an excellent installation begins with choosing the right material for your specific application. According to a study by the American Institute of Steel Construction, steel strut hinges can provide superior durability in heavy-load environments compared to plastic alternatives. Furthermore, hinges that are incorrectly installed can lead to premature failure; a misalignment of just a few degrees can decrease the lifespan by up to 30%, as per the Mechanical Failures Prevention Group's findings.

Routine maintenance of strut hinges is equally vital. Regular inspections should be scheduled, ideally every six months, to check for signs of wear or corrosion, particularly in outdoor applications where environmental factors can accelerate degradation. Lubricating the hinges with high-quality grease can also extend their functionality significantly. The National Maintenance and Repair Association recommends using lithium-based grease due to its excellent adhesion properties and resistance to water washout, which can further enhance performance in varying conditions. By prioritizing these installation and maintenance strategies, users can ensure their strut hinges function effectively for years to come.

This chart illustrates the average weight capacity (in lbs) of various strut hinges based on their sizes, helping you to select the right one for your next project.