Leave Your Message

In industrial settings, the efficiency and precision of manufacturing processes greatly depend on the tools employed, among which

the Adjustable Toggle Clamp stands out as a key component. According to a recent report by

MarketsandMarkets, the global clamping tools market is projected to reach USD 9.2 billion by 2025,

driven primarily by the growing demand for automation in manufacturing. Adjustable Toggle Clamps offer unparalleled

versatility, allowing for rapid adjustments and secure holding in various

applications, from woodworking to metalworking. Their ability to enhance workflow efficiency and improve safety standards

positions them as essential tools in modern industrial practices. Understanding the diverse applications and benefits of

Adjustable Toggle Clamps can empower manufacturers to optimize their operations and adapt

to the changing landscape of production needs.

In industrial settings, the efficiency and precision of manufacturing processes greatly depend on the tools employed, among which

the Adjustable Toggle Clamp stands out as a key component. According to a recent report by

MarketsandMarkets, the global clamping tools market is projected to reach USD 9.2 billion by 2025,

driven primarily by the growing demand for automation in manufacturing. Adjustable Toggle Clamps offer unparalleled

versatility, allowing for rapid adjustments and secure holding in various

applications, from woodworking to metalworking. Their ability to enhance workflow efficiency and improve safety standards

positions them as essential tools in modern industrial practices. Understanding the diverse applications and benefits of

Adjustable Toggle Clamps can empower manufacturers to optimize their operations and adapt

to the changing landscape of production needs.

In manufacturing settings, adjustable toggle clamps are essential tools for ensuring the secure positioning of workpieces. However, they are not without their common challenges. One significant issue reported by industry experts is the wear and tear of clamp components, particularly under repeated use.

According to a study published in the Journal of Manufacturing Processes, approximately 30% of machinery failures are attributable to improper maintenance of clamps, highlighting the necessity for regular inspections and timely replacements to maintain operational efficiency.

Another concern is the adjustment mechanism itself. In a survey conducted by the Manufacturing Institute, it was found that 42% of operators struggle with the precision of adjusting toggle clamps for varying workpiece sizes. This often leads to improper clamping pressure, which can affect product quality and yield.

Many manufacturers are now investing in ergonomic designs and automated adjustment systems to alleviate these issues, reflecting a growing trend towards enhancing usability while maintaining reliability in assembly processes.

Adjustable toggle clamps are essential tools in various industrial applications, offering flexibility and efficiency in securing workpieces. However, improper adjustment of these clamps can severely impact their performance and, more critically, the safety of the operators. When a toggle clamp is not set correctly, it may either apply excessive pressure on the workpiece or fail to hold it securely, leading to slippage or movement during operations. This can result in inaccurate outcomes or even damage to the components being worked on.

Moreover, the implications of improper adjustments extend beyond mere inconvenience. Safety is a paramount concern in any industrial setting. An incorrectly adjusted clamp increases the risk of accidents, including tool malfunctions, injuries, and equipment damage. Operators must be trained to recognize the signs of a poorly adjusted clamp and understand the importance of regular checks to ensure optimal functionality. By prioritizing proper adjustment techniques and ongoing training, industries can enhance not only the performance of their toggle clamps but also safeguard the well-being of their workforce.

When exploring the versatility of adjustable toggle clamps, it's essential to conduct a comparative analysis of the various types available in the market and their inherent limitations. Toggle clamps are widely used in industrial applications due to their ability to securely hold workpieces during machining, assembly, and welding processes. According to recent industry reports, the global toggle clamp market is projected to grow significantly, with an expected compound annual growth rate (CAGR) of approximately 5.58% from 2023 to 2030. This growth is driven by the demand for efficient and reliable clamping solutions across various sectors.

Different types of toggle clamps—such as horizontal, vertical, and push-pull clamps—offer unique benefits and limitations in terms of usability and application. Horizontal clamps, for instance, are excellent for providing consistent pressure but might require more space, while vertical clamps are better suited for tighter work areas but may not hold larger workpieces as securely. Additionally, as the industry evolves, the introduction of advanced materials and designs also presents challenges, including the adaptability of clamps for specialized tasks and the potential for increased costs. Understanding these nuances is crucial for businesses looking to optimize their manufacturing processes.

Adjustable toggle clamps are indispensable in various industrial applications, offering a perfect blend of functionality and adaptability. However, to ensure their longevity and optimal performance, implementing effective maintenance practices is crucial. According to a report by the Industrial Maintenance Institute, routine maintenance can increase equipment lifespan by up to 30%. Regular inspections of the clamp mechanisms, ensuring they are not obstructed by debris or rust, can prevent common malfunctions that disrupt workflow.

Lubrication is another key factor in maintaining adjustable clamps. The American National Standards Institute (ANSI) recommends using high-quality lubricants specifically formulated for metal-to-metal contact. Proper lubrication not only reduces wear and tear but also enhances the clamping action, improving overall efficiency. Furthermore, checking the alignment and tension of clamps regularly can address common issues related to jigging and misapplication, which can lead to operational failures. By investing time in these maintenance practices, industries can mitigate risks, maximize productivity, and prolong the service life of adjustable toggle clamps.

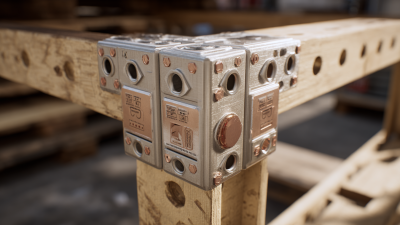

Adjustable toggle clamps have emerged as essential tools across diverse industrial applications, thanks to their ability to securely hold materials in place while allowing for quick adjustments. The innovative design of these clamps enhances their functionality, making them adaptable for various tasks—from assembly lines to woodworking. With features such as adjustable arm lengths and ergonomic handles, operators can customize the clamping force and angle to fit specific requirements, improving efficiency and precision in production processes.

Moreover, the integration of advanced materials and technologies has further expanded the capabilities of adjustable toggle clamps. For instance, some models now incorporate durable synthetic compounds that reduce wear and tear, ensuring longevity in demanding environments. Additionally, the development of quick-release mechanisms allows for faster transitions between tasks, minimizing downtime and increasing productivity. These innovations not only streamline operations but also provide engineers and manufacturers with smart solutions that cater to a wide range of situations, enhancing overall operational effectiveness in the industrial sector.